UT1604 Co-planar Membrane Hydrophone

The 0.4 mm co-planar membrane hydrophone is one of a range of membrane manufactured by Precision Acoustics Ltd. It is designed to be used in conjunction with our standard submersible preamplifier and power supply to form a hydrophone system. Whenever properties are reported in this data sheet they refer to those of a hydrophone system incorporating a 0.4 mm co-planar membrane hydrophone, preamplifier and power supply.

The 0.4 mm co-planar membrane hydrophone is a gold-standard hydrophone that provides excellent sensitivity, frequency response, directional response, dynamic range and noise equivalent

pressure for measurements in the 1 MHz to 40 MHz range. The 0.4mm active area sensitivity that signals ≈ 14 kPa can be measured.If a system with a higher sensitivity is required, the UT1604

can be supplied with an optional matched signal amplifier that provides switchable x1 or x5 gain.

The basic information of hydrophones is as follows:

Model Number | UT1604 |

Sensor element dimensions | Diameter: Film thickness: 16 μm

| 0.4 mm |

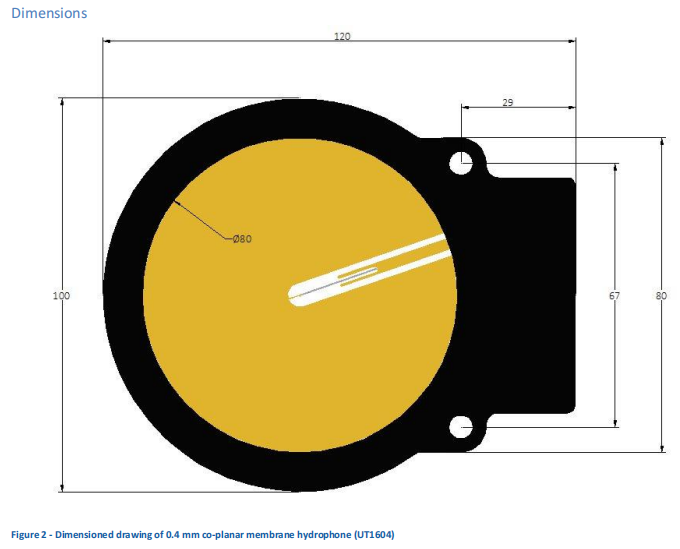

Hydrophone dimensions | See Figure 2 |

Weight of hydrophone | 65 g (without preamplifier) |

Transduction method | Piezoelectric conversion |

Sensor material | Polyvinylidene Fluoride (PVDF) |

Mean sensitivity in the range 2 MHz to 20 MHz | 35 mV/MPa (additional data below) |

Device-to-device variation | ± 3 dB |

Hydrophone frequency band | 0.1 MHz to 40 MHz |

Measurement uncertainty | 0.1 MHz to 1 MHz: 8 % 1 MHz to 8 MHz: 9 % 9 MHz to 20 MHz: 11 % 21 MHz to 30 MHz: 12 % 31 MHz to 40 MHz: 15 % |

Output impedance of hydrophone system | 50 Ω |

Orientation during use | Membrane surface orthogonal to the acoustic axis of the source |

Lower dynamic limit

The noise floor of the hydrophone assembly limits the measurement of small acoustic signals. The noise level of the pre-amplifier is approximately 60 µV rms over a 100 MHz bandwidth. If the hydrophone sensitivity is assumed to be 340 mV/MPa, the noise level stated leads to a noiseequivalentpressure for the 0.4 mm co-planar membrane hydrophone

The data acquisition system being used to record the waveforms produced by the hydrophone can also limit the minimum recordable signal. For example, an oscilloscope that is limited to a maximum resolution of 0.5 mV will only be able to display signals of amplitude 0.5 mV / 35 mV/MPa = 14 kPa or greater.

Upper dynamic limit

Concerning the pressure threshold above which mechanical damage occurs to hydrophone: the this hydrophone has been designed to withstand ultrasonic pressures up to 10 MPa. Although hydrophones of this type have been used for ultrasonic fields that exceed 50 MPa, there is an elevated risk of damage. The supplier’s advice should be sought if the hydrophone is to be used in fields acoustic pressure levels beyond 10 MPa.

Concerning the pressure beyond which amplifier saturation occurs: the pre-amplifier that is used with this hydrophone can start to exhibit nonlinearities when its output voltage exceeds a 700 mV peak-to-peak. Taking into account the typical 0.4 mm co-planar membrane hydrophone sensitivity, this corresponds to a pressure of

Attention should be paid to use:

1、This hydrophone can be used for measurement over an operating temperature range of 5 °C to 50 °C and can be stored over the range 5 °C to 50 °C. Exposure to temperatures above 60 °C has the potential to cause irreversible damage to the hydrophone.

This hydrophone assembly has been calibrated at a temperature between 19 °C and 25 °C. The sensitivity of the hydrophone will be a function of temperature and an increase in the sensitivity of 0 .4 % per degree temperature rise should be expected.

2、The hydrophone assembly has been designed for complete immersion in water and can easily with stand the hydrostatic pressure caused by 2 m of water. Although the hydrophone assembly can be used for prolonged periods (>48 h) of immersion,the hydrophone should be withdrawn from water and allowed to dry whenever it is not in use.

3、Prolonged immersion in water that has not been deionized (e.g. tap water) can lead to a build-up of deposits on the hydrophone. Calcium carbonate deposits can be a particular problem in "hard" water areas and will lead to a loss of sensitivity of the hydrophone.

4、Examples of materials that should be avoided are:

• concentrated acids (e.g. nitric acid, sulphuric acid);

• concentrated alkalis (e.g. sodium hydroxide);

• strong organic solvents [e.g. many aldehydes, many ketones, Dimethyl Chloride (DMC), dimethylformamide (DMF)].

The above is the detailed information of PA hydrophone, if you have any questions about the price, model and picture of PA hydrophone, please contact us modern hero technologies(shenzhen) CO.,LTD to get the latest information of PA hydrophone.